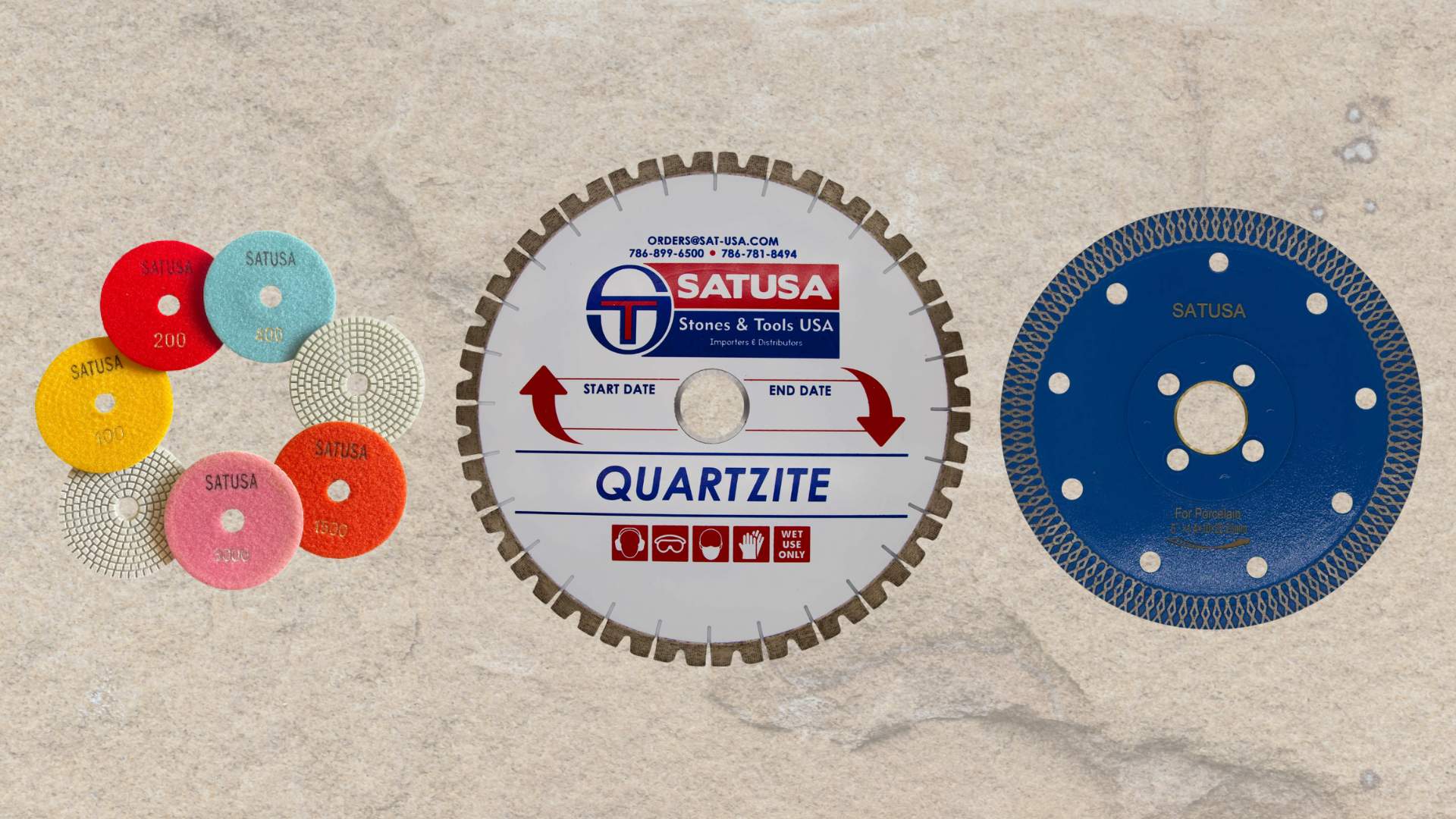

When it comes to stone fabrication, professionals know that the right tools can make all the difference. At Satusa Tools, we understand the unique challenges faced by fabricators and installers. That’s why our high-performance cutting tools are specifically engineered for ultra-compact surfaces like Dekton, granite, quartz, and porcelain.

Discover how Satusa Tools deliver superior durability, precision, and performance—helping you increase productivity and reduce operational costs.

Understanding Cutting Tool Durability

The Importance of Durability in Cutting Tools

Stone fabrication demands tools that perform reliably under intense conditions. Our diamond blades are designed for long-term use, providing:

- Reduced Material Waste: Longer blade life minimizes frequent replacements.

- Cost-efficiency: Fewer replacements translate to lower operational costs.

- Consistent Results: Maintain cutting quality across multiple projects.

Satusa’s Proprietary Technologies

Our exclusive Pent Formula enhances both the cutting speed and durability of our diamond blades—essential for working with today’s toughest materials.

- Vibration-Free Cutting: Prevents chipping and ensures clean, smooth edges.

- Efficient Heat Dissipation: Extends blade life during continuous use.

Cutting Techniques for Ultra-Compact Surfaces

Specialized Blades for Each Material

Selecting the right blade is key for each type of surface:

- Granite & Quartz: Choose blades with higher diamond concentration for accuracy.

- Dekton: Use blades specifically designed for ultra-compact materials to avoid fractures.

- Porcelain: Opt for blades offering smooth finishes to minimize waste.

Tips for Optimal Cutting Performance

- Adjust Feed Rates: Tailor speed based on material density for cleaner cuts.

- Use the Correct Depth: Prevent overloading and reduce premature wear.

- Implement Cooling Techniques: Regular cooling preserves tool integrity.

Product Comparisons and Performance Insights

Satusa Tools vs. Competitors

Compared to standard market blades, Satusa Tools offer superior performance in several key areas:

- Cutting Speed

- Blade Longevity

- Edge Precision and Cut Quality

Engineered with advanced technology and premium materials, our blades are a smart investment for serious professionals.

Solutions to Industry Challenges

Common Pain Points in Stone Fabrication

From slab breakage to unexpected downtime, fabricators face multiple challenges. Satusa Tools offers real solutions:

- Proven Reliability: Backed by industry testimonials citing better performance and reduced tool failures.

- Cutting-Edge Design: Our blades are built to last, decreasing workflow interruptions.

Maintenance Tips for Tool Longevity

How to Keep Your Blades in Peak Condition

- Inspect Regularly: Check for wear, cracks, or damage before use.

- Store Properly: Keep blades dry and secure to avoid corrosion or deformation.

- Replace on Time: Monitor performance and replace before tool degradation affects cut quality.

Maximize Your Fabrication Results with Satusa Tools

Satusa Tools leads the industry with professional-grade cutting solutions that offer lasting durability and precision. Whether you’re managing a fabrication shop or installing high-end countertops, our blades are designed to support your work and improve results with every cut.

Contact Us Today!

Ready to upgrade your tools and boost your performance?

- Email: orders@sat-usa.com

- Phone: (786) 899 6500

- Website: satusatools.com