Modern construction and design materials have evolved significantly, offering new options that are both stylish and durable. One of the most innovative among them is Dekton, an ultra-compact surface composed mainly of glass, porcelain, and quartz. Highly valued for its strength and versatility, Dekton presents a unique challenge for professionals due to its extreme hardness and density. This raises a crucial question: How can you cut Dekton without chipping? In this article, we’ll explore best practices and the right tools to achieve clean, precise cuts while preserving the integrity of this premium material.

The Art of Chip-Free Cutting: Understanding the Science Behind Dekton

Dekton stands out for its dense, homogeneous composition, created through a cutting-edge process known as sinterized particle technology. This process enhances the internal cohesion of the material, making it highly resistant to stains, heat, and UV exposure. However, these same properties also make it prone to chipping during cutting operations.

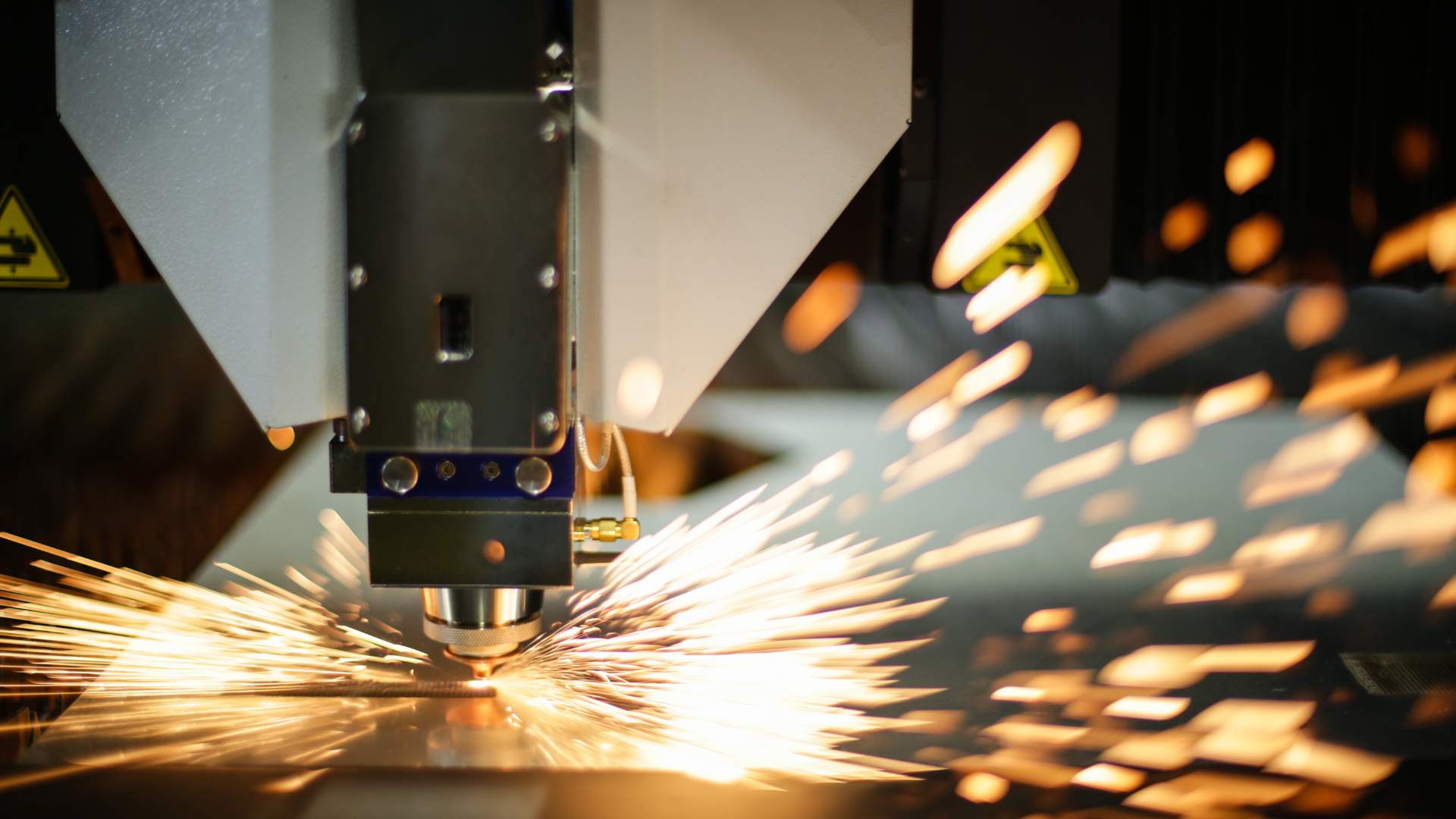

To overcome this, professionals must use the right blade for the job: diamond blades engineered specifically for ultra-compact surfaces. These blades are designed to cut through tough materials delicately, reducing the risk of irregular edges often associated with Dekton cuts.

The key lies in using a high-quality diamond blade that is sharp and guided with proper technique. Cuts should be performed at a consistent and controlled speed, avoiding excess pressure and allowing the tool to do the work. Smooth motion and adequate water lubrication during cutting are essential to prevent heat buildup and blade wear, ensuring a chip-free finish.

Technology & Testimonials: Practical Ways to Improve Your Dekton Cuts

A breakthrough in cutting technology is the introduction of the Pent Formula, which dramatically enhances cutting performance on ultra-compact surfaces. This innovation extends tool life and promotes smoother cuts by significantly reducing friction. Fabricators using this technology report less tool wear and cleaner edge finishes, resulting in considerable savings on tools and labor.

Take, for example, a countertop fabrication shop that started using diamond blades specifically designed for Dekton, combined with Pent Formula technology. They reported a 30% increase in operational speed and a 70% reduction in cutting defects. Employees also noticed significantly less noise and vibration during operation, creating a better work environment and boosting both precision and confidence in the tools used.

Efficient cutting techniques not only prolong the life of your tools—they also allow you to get the most out of Dekton without compromising its intrinsic beauty. Another industry professional shared how upgrading to premium blades, paired with proper cooling systems and holding fixtures, completely transformed the quality of their cuts and allowed them to deliver finishes they once thought were impossible.

Conclusion: Cutting Dekton the Right Way

In the end, cutting Dekton without chipping comes down to a smart combination of specialized tools, refined techniques, and innovative technologies like the Pent Formula. By understanding the material’s unique characteristics and how to work with them, professionals can optimize fabrication processes and deliver flawless results that meet the high standards of clients and craftsmen alike.